Capability - Friction Welding

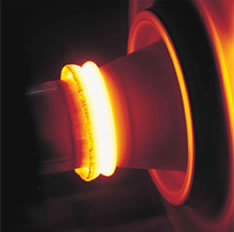

Friction welding, is a process of solid state welding that generates heat through mechanical friction.

Advantages

- Considerable product improvement (joint strength equal to or greater than the parent material), plus ability to join dissimilar metals.

- Labour, material and operational cost savings

Number of Machines -- Two

Capacities-600mm long x 75mm weld diameter

Tonnes Pressure --60t

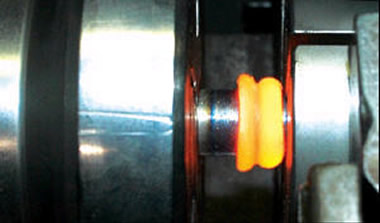

The benefit of joining dissimilar diameters to reduce material cost has been established through many years of development.

Spenco has taken this further by pre machining components before friction welding to another component, hence resulting in cheaper routes to produce machined blind bores.

Spenco has considerable experience in friction welding bar material to both forgings and castings, significantly reducing material costs.

A proven quality assurance route to verify the resulting quality of product weld is established, test samples can be provided, and in house bend tests and macro examination are all established routes of quality control.